Features:

- 500 HP rated

- Perfect for daily driving

- Great for consumer level towing

- Features improvements over the OE 5.9L

- 5 Year / 100,000 Mile Warranty

Excels at Performing in Daily Tasks

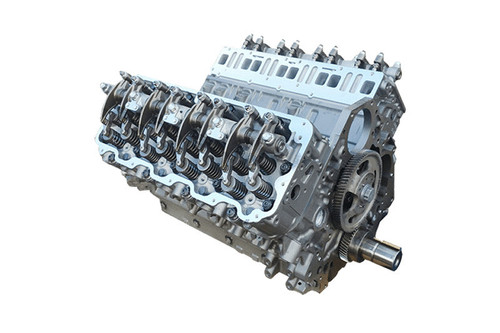

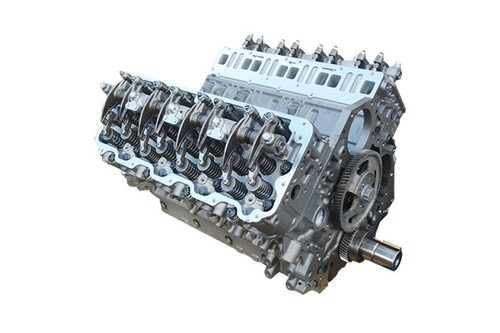

The 6.6L Daily Driver Short Block is designed to be the perfect daily driver engine. Choate Engineering puts a big emphasis on creating this engine to enable spirited daily driving that makes you enjoy driving your truck every day. Additionally, this assembled professionally in-house engine is more than capable of consumer level towing such as boats or RV trailers. For improved power and reliability over the OE 6.6L, the 6.6L Daily Driver Short Block is the perfect choice.

Upgraded and Improved 6.6L

Choate Engineering designed their 6.6L Daily Driver Long Block LBZ includes components built to stringent standards to ensure your 6.6L is operating at full capacity. These parts include Choates in-house-built heads, Pressure Test Heads, Grind Valves, New Induction Hardened Seats, All New Valve Guides, New Valve Seals, New Freeze Plugs, New Injector Cups. Additionally, there are upgraded pistons to maximize durability and eclipse the OE 6.6L's reliability. These new upgraded pistons are .10-.30 inch thicker than stock with new rings and pin retainers that come fully weight matched prior to crank balancing. The engine is also fully blueprint machined to ensure proper clearances and maximize efficiency. Choate Engineering's 6.6L Daily Driver Long Block is the perfect upgrade or replacement of the OE 6.6L and offers a reliable and fun driving experience.

Fits: 2006-2007 GM 6.6L Duramax LBZ

Applications Notes:

- Optional Parts are not installed. Optional parts are covered under the manufactures warranty and not by CHOATE

Build Features:

- The Cylinder bores are blue print bored to a true 90 degrees from the crankshaft center line, prior to being diamond honed to within .0002 inch for precise piston to cylinder bore clearances.

- We main bore and line hone the crankshaft which is honed to precisely align the crankshaft in the engine block.

- We bore the block back to the crankshaft center line and hone the block to RA13 finish.

- The piston diameter measured to the nearest .0001 inch matched to cylinder bores.

- The Cylinder block is surfaced to a finish of RA30 or lower, which meets the factory specification in both flatness and smoothness for the block to head sealing surface.

- This is mandatory for proper sealing of a MLS Gasket.

- Connecting Rods, New Damper and Flexplate for Automatic transmission. All Manual will be charged the appropriate charges and will be balanced to a stock flywheel we have in stock or you will need to send in your Aftermarket in first.

- Check both wrist pin and crank pin to rod clearances

- New Upgraded Pistons .10 – .30 inch over – New Pistons, Rings, Pin Retainers weight matched prior to crank balancing

- New OE Lifters, Lifter Guides, OE Crank Flange Bolts, Updated 9.800 OE Pushrods

- Crankshaft – Balanced with the Rotational assembly checked for run-out inspected for fatigue.

- Crankshaft is Polished and ground to .0005 concentricity or less

- Camshaft – Polished and Inspected

- New Rod, Main and Cam Bearings

- Install Rear Main Seal

- Install New Bed Seals

- Install New Rear Cover Gasket

- Install Upper and Lower Oil Pan Gaskets

- Install Pickup Tube O-ring

- Rear Cover Installed

Note: $500 Shipping surcharge will be added at checkout

Warning: This product can expose you to chemicals that are known to the State of California to cause cancer. For more information, visit [www.P65warnings.ca.gov]

Choate Engineering CEP66LBZLD 6.6L Duramax Daily Driver Long Block | 2006-2007 GM Silverado/Sierra 2500HD/3500HD 6.6L Duramax LBZ

Choate Engineering

MSRP:

Was:

Now:

(Inc. Tax)

MSRP:

Was:

Now:

$12,750.00

(You save

)

(No reviews yet)

Write a Review

Write a Review

Choate Engineering

Choate Engineering CEP66LBZLD 6.6L Duramax Daily Driver Long Block | 2006-2007 GM Silverado/Sierra 2500HD/3500HD 6.6L Duramax LBZ

- SKU:

- CHTCEP66LBZLD

- UPC:

Add to Cart

The item has been added

Choate Engineering

Choate Engineering CEP66LBZLW 6.6L Duramax Workhorse Long Block | 2006-2007 GM Silverado/Sierra 2500HD/3500HD 6.6L Duramax LBZ

MSRP:

Was:

Now:

(Inc. Tax)

MSRP:

Was:

Now:

$14,800.00

Add to Cart

The item has been added

Choate Engineering

Choate Engineering CEP66LBZSD 6.6L Duramax LBZ Short Block Daily Driver Crate Axle | 2006-2007 GM Silverado/Sierra 2500HD/3500HD 6.6L Duramax LBZ

MSRP:

Was:

Now:

(Inc. Tax)

MSRP:

Was:

Now:

$9,000.00

Add to Cart

The item has been added

Choate Engineering

Choate Engineering CEP66LBZSW 6.6L Duramax Workhorse Short Block | 2006-2007.5 GM Silverado/Sierra 2500HD/3500HD 6.6L Duramax LBZ

MSRP:

Was:

Now:

(Inc. Tax)

MSRP:

Was:

Now:

$11,100.00

Add to Cart

The item has been added

Choate Engineering

Choate Engineering CEP66LMMLW 6.6L Duramax Workhorse Long Block | 2007-2010 GM Silverado/Sierra 2500HD/3500HD 6.6L Duramax LMM

MSRP:

Was:

Now:

(Inc. Tax)

MSRP:

Was:

Now:

$15,000.00

Add to Cart

The item has been added

Choate Engineering

Choate Engineering CEP66LLYLD 6.6L Duramax Daily Driver Long Block | 2004.5-2005 GM Silverado/Sierra 2500HD/3500HD 6.6L Duramax LLY

MSRP:

Was:

Now:

(Inc. Tax)

MSRP:

Was:

Now:

$12,500.00

!